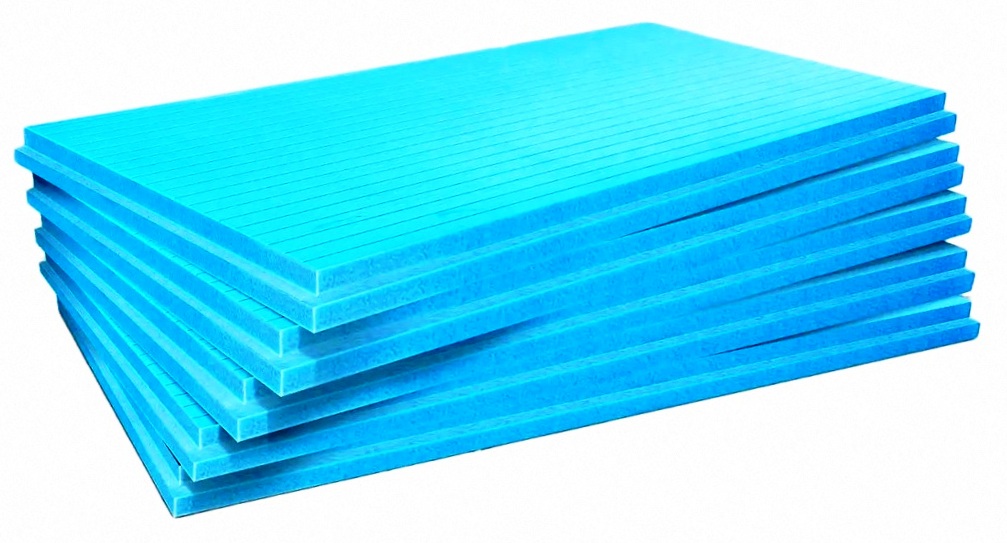

Extruded polystyrene

Showing all 5 results

Quantity per carton

12 product

Quantities per pallet

60 product

Мinimum quantity

100 product

Delivery time

14 days

Quantity per carton

12 product

Quantities per pallet

60 product

Мinimum quantity

100 product

Delivery time

14 days

Quantity per carton

12 product

Quantities per pallet

60 product

Мinimum quantity

100 product

Delivery time

14 days

Quantity per carton

12 product

Quantities per pallet

60 product

Мinimum quantity

100 product

Delivery time

14 days

Quantity per carton

12 product

Quantities per pallet

60 product

Мinimum quantity

100 product

Delivery time

14 days

Extruded polystyrene (XPS) is a high-performance rigid insulation material with a closed-cell structure that makes it impervious to moisture. It is a structural insulator that is available in various grades for specific applications requiring high loading or resistance to excessive moisture levels. It is produced either as a standard construction product or a close tolerance version for panel making applications.

We offer excellent products from manufacturers in the Balkans, excellent prices and which will be delivered directly from the manufacturer.

Extruded polystyrene (XPS) is a lightweight, rigid, and closed-cell foam plastic. It is made by extruding molten polystyrene through a die, which creates a continuous sheet of foam. XPS is then cut into sheets or boards of various sizes and thicknesses. XPS is a versatile material with a wide range of applications. It is commonly used as a thermal insulator in buildings and appliances. It is also used as a packaging material, a flotation material, and a cushioning material. The extruded polystyrene has some of the key properties. XPS is very lightweight, making it easy to transport and handle. It is a rigid material that can withstand a lot of weight. XPS is a closed-cell foam, which means that it is water-resistant and does not absorb moisture. XPS is a good thermal insulator, which means that it can help to keep buildings and appliances warm or cool. And finally XPS can be cut into a variety of shapes and sizes. Extruded polystyrene (XPS) is a versatile material with a wide range of applications due to its excellent properties like being lightweight, rigid, water-resistant, and a good thermal insulator. Here are some common uses: Building and construction XPS is very useful as thermal insulation in construction field: it is used in walls, roofs, floors, foundations, and basements. It is used under slab insulation for radiant heating systems; in roof decks and inverted roofs. It is used in exterior cladding and rainscreen systems. There is also perimeter insulation for foundations and basements. It is used in cavity wall insulation in masonry and timber frame structures. There are cold storage facilities insulated with XPS. Packaging The packaging industry also used XPS, for protective packaging for delicate electronics, appliances, and other sensitive items; food and beverage packaging due to its temperature-control properties; cooler boxes and ice chests. Marine and transportation In marine industry XPS is used as flotation material in boat hulls and life jackets; buoys and navigational markers; packing and cushioning for boats and marine equipment. Agriculture and horticulture In agricultural fields there is thermal insulation for greenhouses and plant propagation benches; mulching material to retain moisture and suppress weeds; packing and support for fragile seedlings and plants. Other applications There are number of DIY activities where XPS could be used, such as: craft and hobby materials; sporting goods, such as helmets and shin guards; furniture components; display fixtures and signage. All starts with the preparation of the surface: the substrate is cleaned to remove dust, dirt, and loose debris. For better adhesion, the surface can be primed. XPS panels are measured and cut to the desired sizes. Use a sharp knife or saw. Fixing method XPS can be fixed in various way, one of which is with adhesive. A suitable XPS adhesive is applied to the back of the panels. The manufacturer's instructions must be followed. There is also method with mechanical fasteners: the XPS panels can be fixed to the substrate with anchors, screws, or nails. There is also a combined method: for increased security, a combination of adhesive and mechanical fasteners can be used. Additional steps Joints are filled with a suitable sealant between the XPS panels. This ensures a seamless and water-resistant finish. Tips Protective gloves and safety glasses are always worn when working with XPS. Sharp cutting tools are used to avoid deformation of the panels. Prolonged exposure to direct sunlight is avoided to prevent damage to the XPS. Manufacturer's instructions for installation and storage are always followed. Important The installation method may vary depending on the specific application, the type of XPS panels, and the substrate characteristics. It is recommended to consult a specialist before starting the installation.

Fields of application ot extruded polystyrene XPS

Extruded Polystyrene (XPS) Installation